A Miniature Lathe Chuck

Part 2

For the chuck jaws I'll use cold rolled steel. The dimensions on this kind of steel are generally held close enough

from the foundry that it can be used as it comes. In other words, if you buy 3/16" thick metal it will really be

3/16", or .188" thick, so if you want it to fit nicely into a slot of that same size, it will be a nice fit. On the

other hand, hot rolled steel is often off the nominal size by .010-.015" and often has to be brought to size by

milling or some other means.

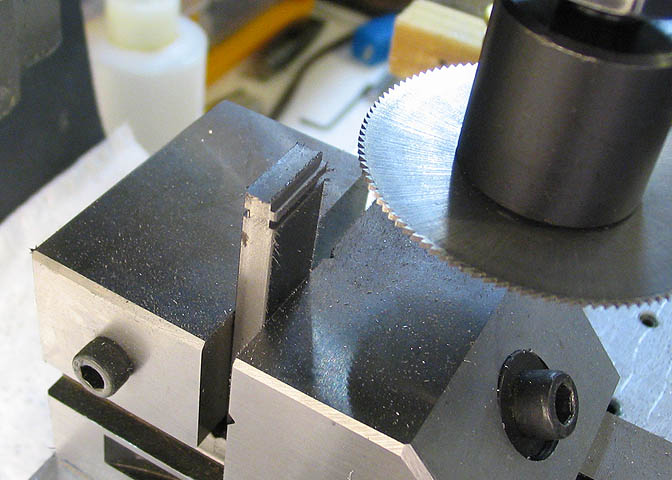

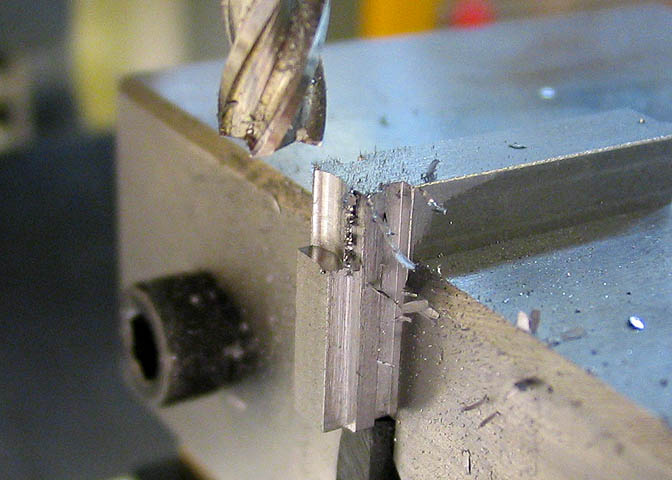

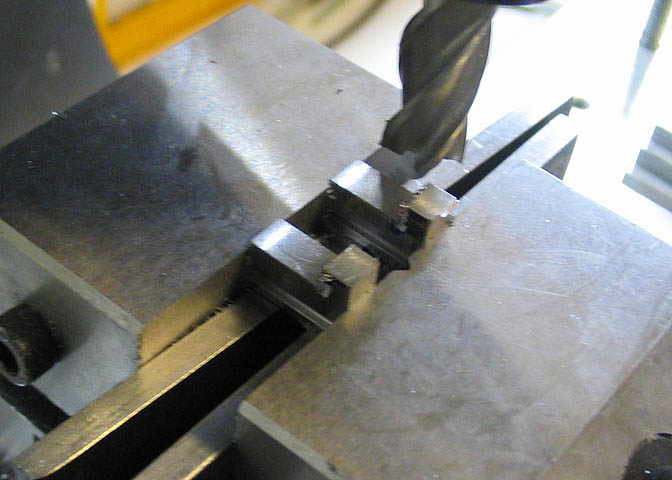

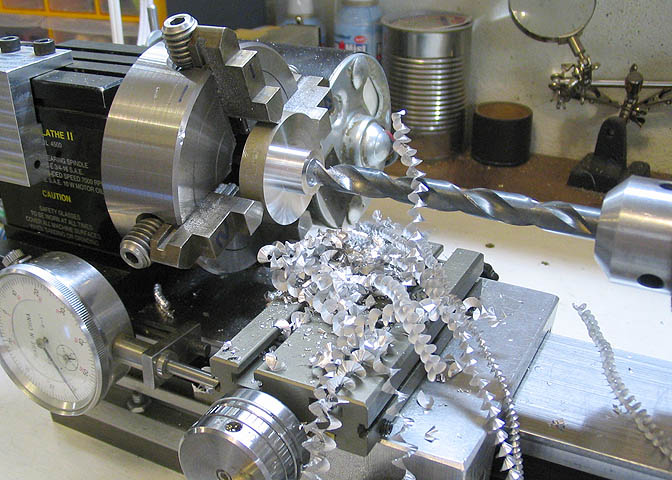

I started with a piece long enough to easily hold in the vise, and using a slitting saw cut in the grooves needed

to match the machining on the chuck body.

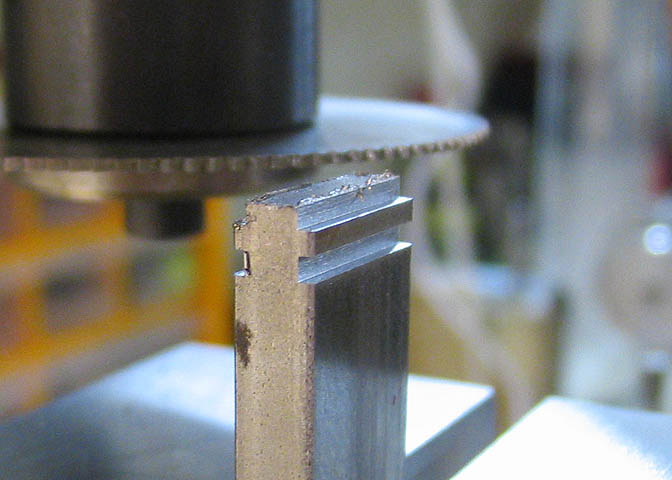

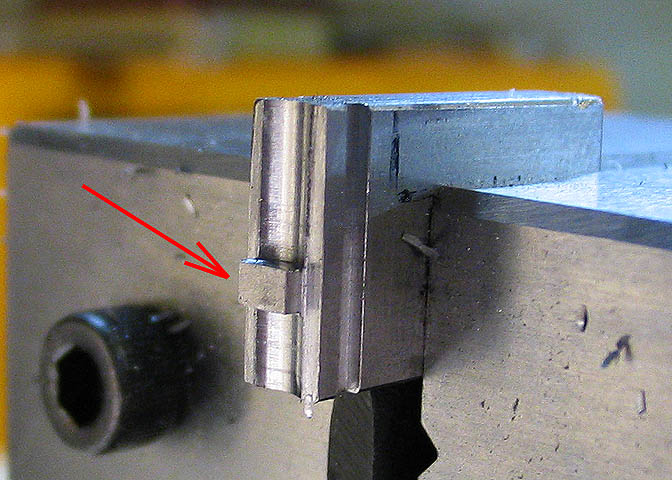

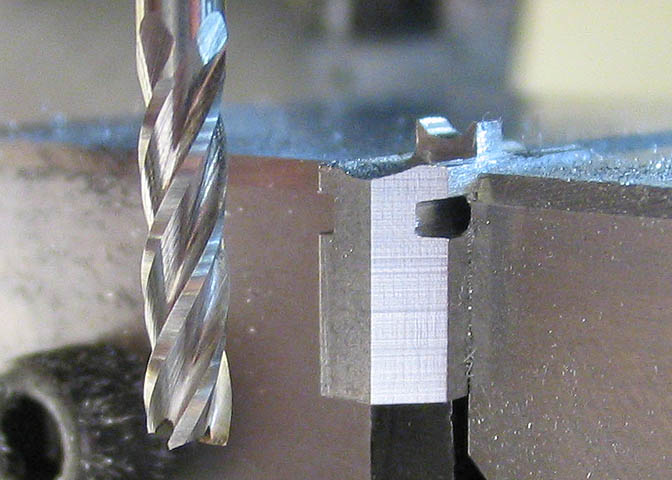

Here's another view of the piece. The saw does a pretty good job, thought not quite as nice a finish as an end

mill would make. I used the saw mainly to save on breakage of miniature end mills. When they get as small as

the slots needed for the jaws, they break pretty easily.

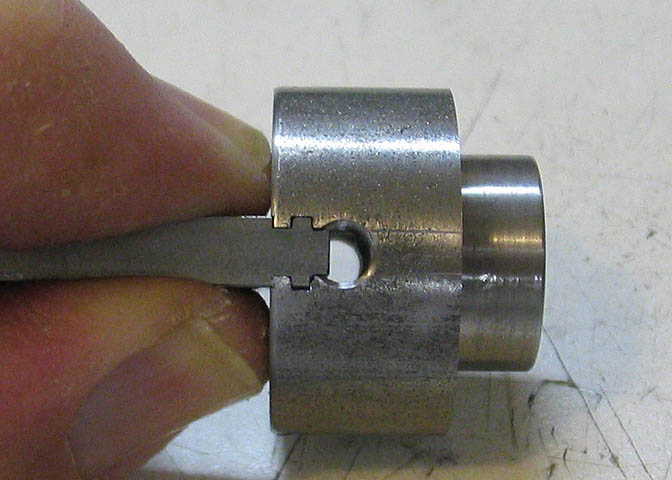

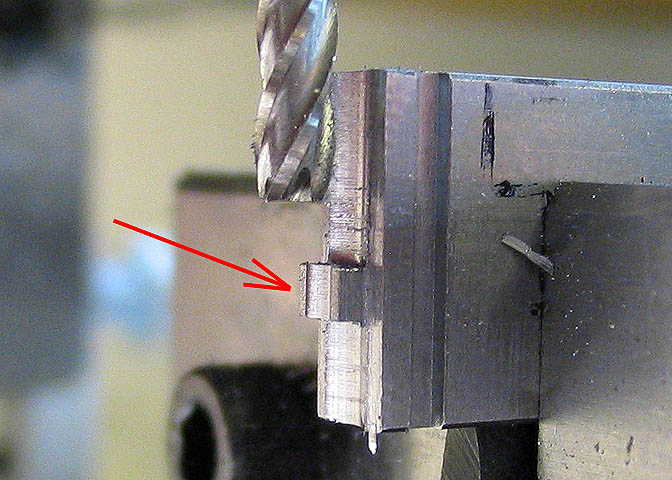

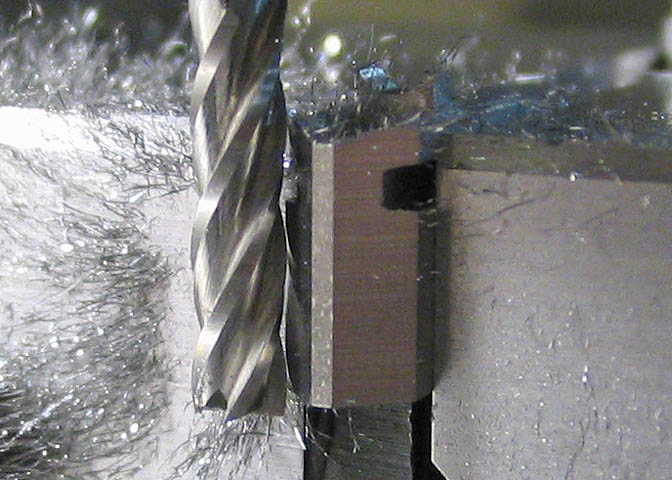

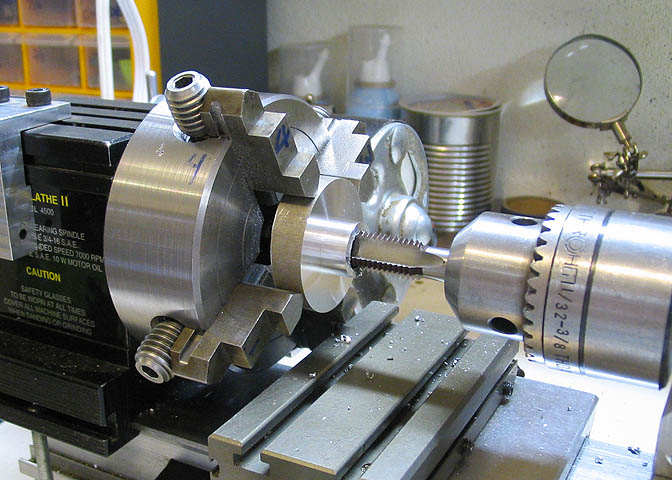

Here's the first try at getting the jaw piece into the chuck body. I spent a bit of finish time with a file

getting rid of the burrs left in the jaw and chuck body that were left from the machining steps.

This one was just used as a test piece, to make sure my dimensions were on before I make a matched

set of four jaws.

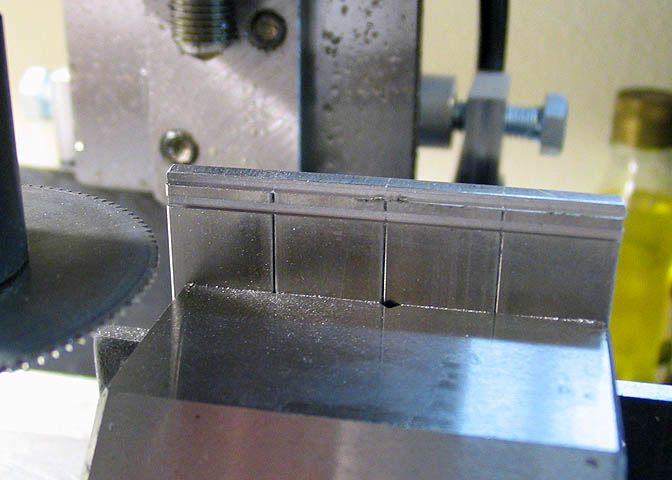

Now that I know I have the correct dimensions for the sliding part of the jaws, I set up four pieces of steel

in the mill vise so I can make them all exactly alike.

Then each piece is milled for a radius that will match the jaw screws.

Turn it over and mill the other side. The block looking piece that is left will be the drive lug for the

jaw screws.

A small radius is milled into that block that will fit over the driving slot in the screw.

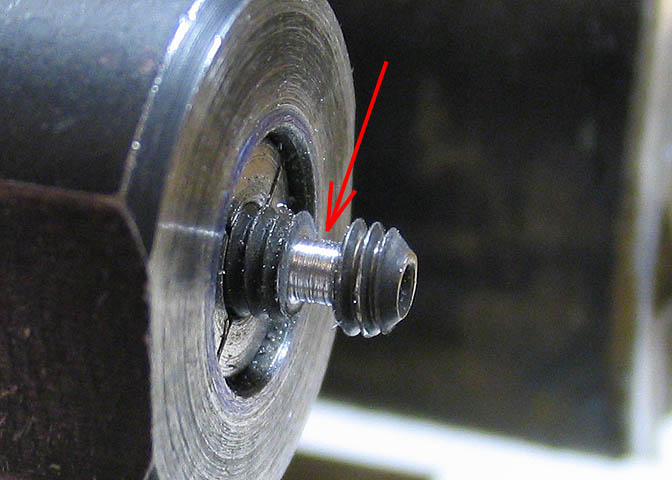

This is the driving slot cut into one of the jaw screws. I'm using 10-32 hardened set screws for this.

The cutting tool has to be good and sharp to cut them. On this one, it wasn't sharp enough, and left

a rough surface inside. Time to break out the Arkansas stone and try again.

Here, you can see the jaw blanks, along with the one finished test jaw and drive screw.

Cutting the steps in the jaws is easy. Apparently, getting a sharp picture of it was not... Sorry.

Then the ends of the jaws have to be beveled, so they come to a point with a small flat in the middle

of that point. The mill vise was set to 45 deg, and one side cut using the X travel on the mill table.

Then the other side is cut using the Y travel of the mill table. To get the angles the

same width on each side I counted how many thousandths in-feed I went on the X table travel, then

cut the same amount on the Y table travel. Once I had as much left in the middle that looked right, I

wrote down the figures, then did the other three jaws the same way, so they all look alike.

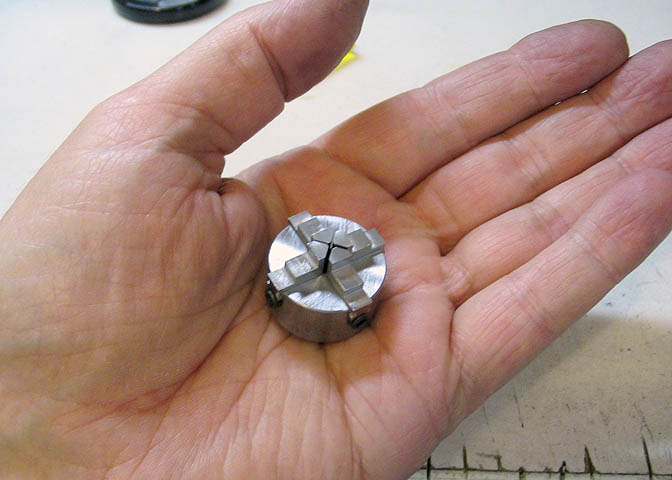

And finally, they are done!

Not bad, I guess. Looks about like a chuck, to me.

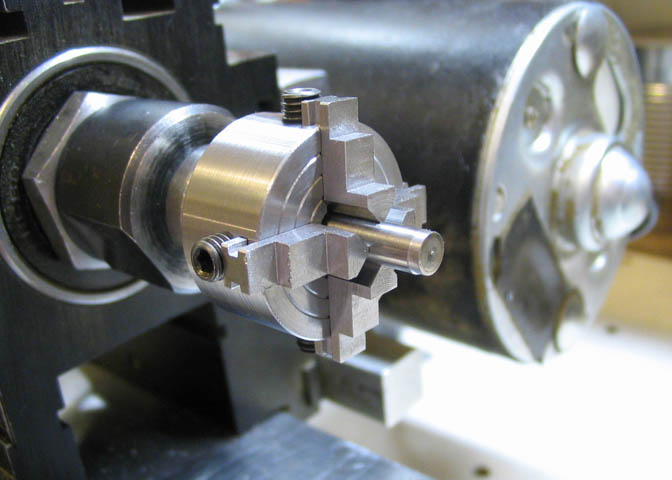

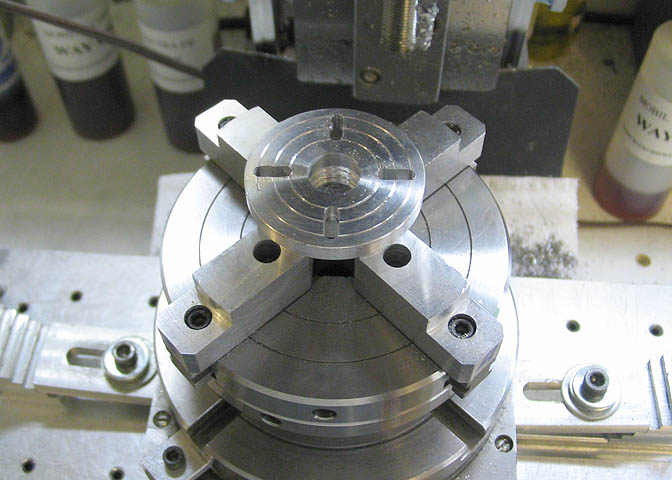

I put Kenneth's new spindle in my small lathe and screwed on the new chuck to check it out.

Works just like the big boys.

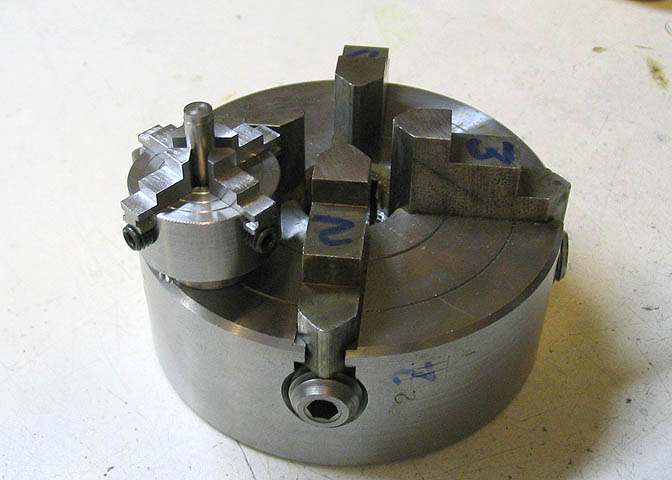

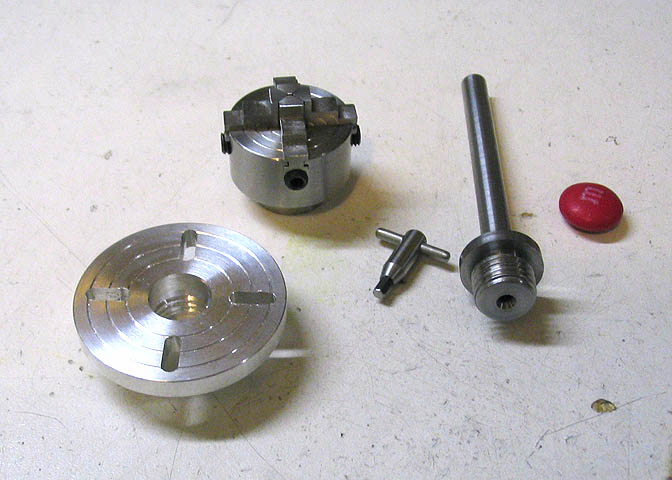

Here it is with the chuck it was modeled on, the stock Taig four jaw.

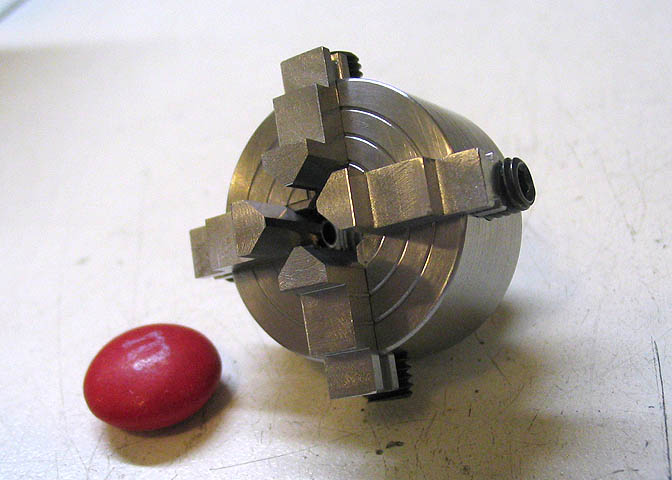

With the M&M machinist's scale.

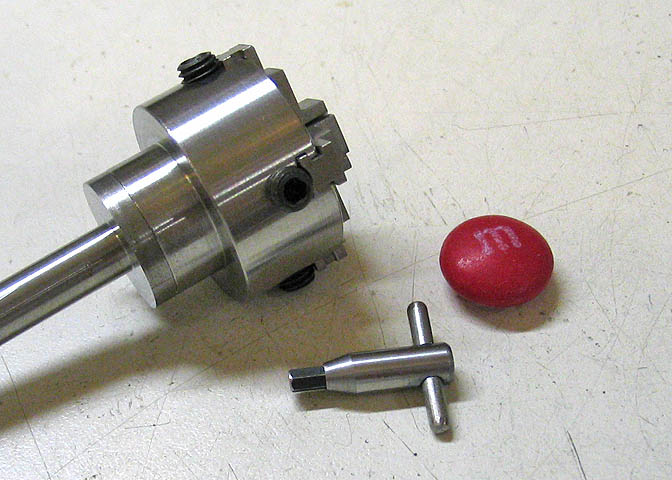

Of course, it has to have a chuck key. The key was made from drill rod, and the hex end was cut

from an Allen wrench. Then the piece of hex is pressed into the key.

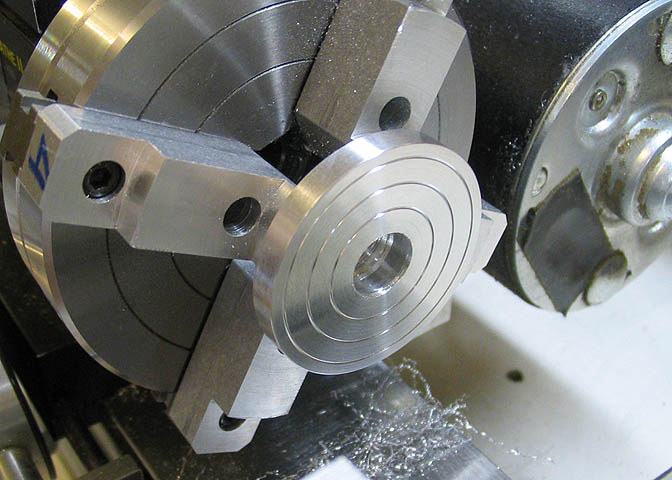

I figured while I was at it, my friend could also use a miniature face plate for his model lathe.

This part is made from aluminum.

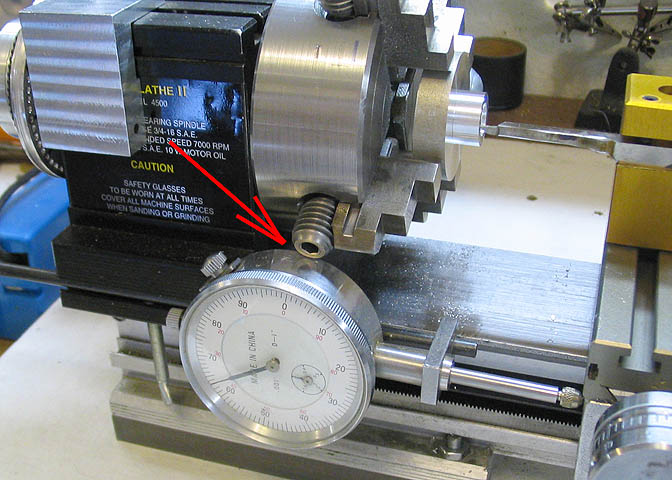

Thought I'd show this while I'm at it. While I don't find Chinese made end mills to be very good,

they do make acceptable dial indicators, which also happen to be very cheap. Cheap as in, if I

bash it with something like a chuck, I won't feel as bad as if I did the same thing to my nice Starrett.

Obviously, this was my own fault!

After boring a hole in the face plate, it's tapped for the same M12 x1.5 threads as was used for the chuck.

Then it's flipped end for end and the face and diameter cleaned up, and centering rings cut in.

Finally, some slots are milled for clamping hardware, and this last piece is done.

That's it for another project. These pieces have since been shipped off to Denmark, and friend Kenneth

now has a little model lathe that is fully equipped.

Thanks for having a look. Hope you found something worth reading.

Back to Part 1

To go back to the main projects page, click the link below.

More Taig Lathe & Mill Projects

Copyright 1998-2012 Dean Williams