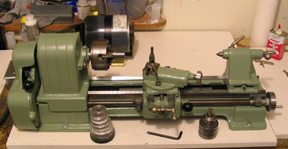

The Craftsman 109 Lathe Project...

One of these little Craftsman lathes landed in my shop not too long ago. I call

it little, but it's the largest of the three lathes in my shop. Everything in my shop

is small, so I guess this is the biggest of the small things.

These lathes are often the source of frustration to their owners. Some first time

lathe buyers start with this one, but it's not really a beginners lathe. It takes some

time and care to make one run well, partly because they were a light machine to

begin with, and partly because even the more recently made ones are old to start

with. The one featured here was made around 1948. That's 61 years old.

In dog years... it would be dead! So, there's a good chance it came to me with

considerable wear from the get go, not to mention what ever abuse it may have

received from previous owners.

These lathes are commonly referred to as the Craftsman 109, or AA109, mainly,

I take it, because they were sold by Sears and all had the model number starting

with a prefix of 109. The AA comes from the company that originally

manufactured them, which was the Ann Arbor Company in Michigan. This

particular model is the 109-20630. They must have made a bunch of them, 'cause

they're everywhere. There were other models, earlier ones looking similar to this

one, and later models with a slightly more modern appearance including a wide

chrome strip on the head stock, but as far as I can tell, they are all the same basic

machine. Some older ones had narrower ways, some had longer beds.

I mentioned above that I don't really think this is a good candidate for a beginner.

I believe they take a bit too much fiddling to get them to really perform, and that

a new hobby machinist may become frustrated with them. A better choice in my

opinion would be the Taig lathe, my personal favorite, or the Sherline lathe. I've

owned both these makes and they are both fine machines, able to do very precise

work right out of the box, and easier for the beginning home machinist to work with.

That's not to say that someone shouldn't get one a 109. They can be set up to do good

work. It's just that to get one to work for you, you have to work for it a little, too.

The ups and downs of it all.

First thing you need to realize is, the 109 lathe is what it is. A small, light machine.

The spindle is only .550" in diameter, and it runs in plain bearings. These bearings

need to be in good shape and properly adjusted to do good work.

The spindle bore is only 1/4", and the tapers are little #0 Morse size, so it can't

be expected to swing a 6" hunk of iron, even though it's a 6" lathe.

All the screws are American thread, which is usually considered a good thing when

considering a lathe for us American type folks, BUT, they all have a goofy pitch.

The "not-easy-to-divide-by-thousandths" type, like 16 pitch on the lead screw,

and 24 pitch on the cross slide and compound. Plus there are no graduated dials.

Something that you will have to make yourself if you want 'em.

The gibs as they came from the factory were not a very good design. The upshot

is they are easy to modify for better adjustments.

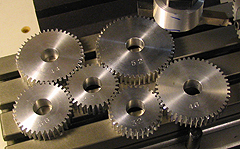

Most of these lathes have full thread cutting ability, and will cut a lot of pitches.

The fine feeds are kind of nice for roughing out stock.

Lastly, they are pretty easy to work on for people even mildly mechanically minded,

and the fixes and care needed to make them run well are not rocket science.

So, after all that blabbering, here's where the project begins, with links to the start of it below.

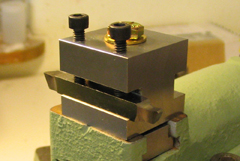

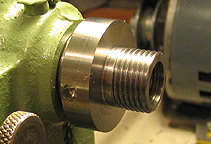

109 Rebuilding notes and comments  A Better Tool Post for the 109  109 Tail Stock Ram Refit |

Cutting Change Gears for the 109  A 3/4-16 Spindle Adapter for the 109 |

More Taig Lathe & Mill Projects

deansphotographica.com

(home page)

Copyright Dean Williams